ချီးနား Huangjiaba ကုမ္ပါဏီ, Santai County, Sichuan province, ချီးနား +86-15359596380 [email protected]

Color: Green

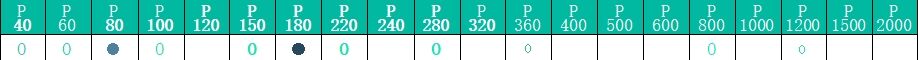

Grit: P40-P2500

ပစ္စည်း။

အာဘရေးသီးသံဃာ: အမြင့်တန်း အလူမီနီယမ် ၊ သို့မဟုတ် ဆီလီကွန်ကာဗိုင်း

ဘက်ကင်: တိုက်ရိုက်မြင့်တန်း PET (polyester) ရောင်ဗျူးဖြင့် လွယ်ကူစွာ တွေ့ရှိနိုင်စေရန်

အားကြီးပေးသူ: အားကြီးသိမှားသော သို့မဟုတ် အီလက်ထရိုနီက် အားကြီးပေးသူ

ဒီဇိုင်း:

Grit Range: P120-P800 (ကြေးသော သို့မဟုတ် ပြောင်းလဲသော)

အိုင်းများ အရွယ်အစား:

အိုင်းမရှိ: စတိုင်ဒါး ပြင်ဆင်ထားသော နောက်ပိုင်း

တစ်အိုင်း: အိုင်းထုတ်ခြင်း စနစ်များအတွက် အလယ်အိုင်း

အရောင်ခွဲခြမ်းစိတ်ဖြင့်: ပြီးဝင်သော အမှန်ကို အများအားဖြင့် ဖော်ထုတ်ရန် البنafspurple backing

အသုံးပြုမှုများ:

သိပ္ပံ metal polishing (stainless steel, aluminum)

လှေကားဆိုင်ရာ paint refinishing

Composite material finishing (carbon fiber, GFRP)

Optical lens နှင့် acrylic မျက်နှာ preparation

အကျိုးကျေးဇူးများ

အထူး Flatness: PET backing က performance ကို wrinkles-free ဖြစ်စေသည်

Tear Resistance: paper-backed equivalents ထက် ၃x အကြီးမားသည်

Heat Dissipation: Low-friction surface က burning ကို လျော့နည်းစေသည်

Moisture Proof: water/oil vs paper backings နှင့် မပြင်ဆင်ဘူး

Dust Control: Hole version vacuum systems နှင့် compatible

အသုံးပြုမှု

ထုတ်ကုန်အင်္ဂါရပ်များ:

မြေပြင် ပေါ်ရှိ ကျောက်ဆုံးများ ကိုက်ညီသည်၊ အသုံးအဆ အရှည်ကြာ ဖြစ်သည်၊ ရေနှင့် ဆေးကို မာတ်ဆိုင်းသည်၊ ကောင်းမွန်သော အင်္ဂါမှု အကျိုးသက်ရောက်မှု ရှိသည်။

ပုံမှန် စာသားများနှင့် ရေပြား ဖျင်းခြင်းအတွက် ပြင်ပြင်မှုနှင့် သံုးမှု၏ တူညီမှုကို ယှဉ်ပြခြင်း:

|

|

| ပုံမှန် စာသားများ | ရေပြား ဖျင်းခြင်းအတွက် သုံးစွန့် |

အကျယ်: 1380mm

အခြေခံပစ္စည်း: Polyester thin film/PET

အာဘရေးသီး: မီက်စတ် အာဘရေးသီး

ပံ့ပိုင်း: အာလ်-ရီزن

ပါတီကယ် အရွယ်အစား: P40-P2500

အကျိုးကျေးဇူးများ