When it comes to achieving professional-grade metal finishing results, selecting the right abrasive tool makes all the difference in your project's outcome. A flap disc stands as one of the most versatile and efficient grinding accessories available to metalworkers, fabricators, and DIY enthusiasts alike. These innovative abrasive tools combine the aggressive cutting power of grinding wheels with the smooth finishing capabilities of sanding discs, making them indispensable for both heavy material removal and precision surface preparation tasks.

Understanding Flap Disc Construction and Design

Anatomical Components of Modern Flap Discs

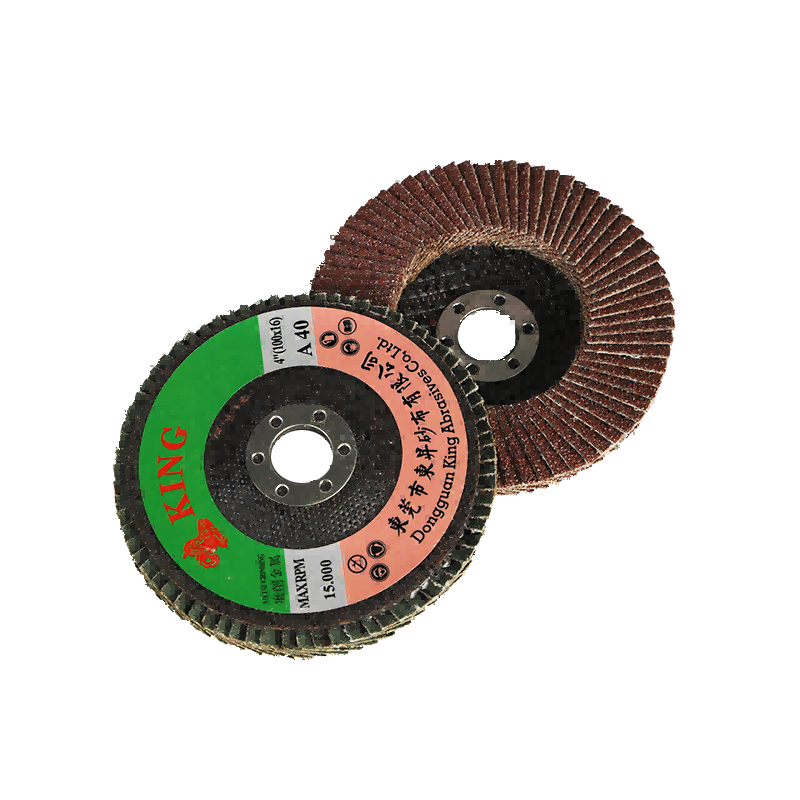

The engineering behind flap disc construction involves multiple layers of abrasive cloth flaps arranged in an overlapping pattern around a central backing plate. Each individual flap contains precisely graded abrasive particles bonded to a flexible cloth substrate, typically made from cotton, polyester, or specialized synthetic materials. The backing plate, usually constructed from fiberglass or reinforced plastic, provides structural integrity while maintaining optimal balance during high-speed rotation.

The density and arrangement of these flaps directly influence the disc's performance characteristics, with higher flap counts generally providing smoother finishes and longer tool life. Manufacturers carefully engineer the flap angle and overlap to ensure consistent material removal rates while minimizing heat generation that could damage sensitive workpiece surfaces. This sophisticated design allows the outer flaps to wear away gradually, continuously exposing fresh abrasive material underneath for sustained cutting performance.

Abrasive Material Technologies

Contemporary flap disc manufacturing employs various abrasive materials, each engineered for specific applications and material types. Aluminum oxide remains the most common choice for general-purpose metalworking due to its excellent balance of cutting efficiency and cost-effectiveness. These grains fracture under pressure to maintain sharp cutting edges throughout the disc's operational life, making them ideal for steel, iron, and other ferrous materials.

Zirconia alumina represents a premium abrasive option that delivers superior performance on harder materials and high-pressure applications. The unique crystalline structure of zirconia provides exceptional heat resistance and self-sharpening properties, resulting in faster stock removal rates and extended disc longevity. Silicon carbide variants excel when working with non-ferrous metals like aluminum, brass, and copper, where their friable nature prevents loading and maintains consistent cutting action.

Performance Characteristics and Applications

Material Removal Capabilities

The primary advantage of using a flap disc lies in its ability to perform multiple operations with a single tool, eliminating the need for frequent accessory changes during complex projects. Initial grinding operations can remove substantial amounts of material quickly, while the same disc can subsequently provide intermediate smoothing and final finishing passes. This versatility significantly reduces project completion times and improves workflow efficiency in professional fabrication environments.

Material removal rates vary considerably based on grit selection, with coarser grades like 36 and 40 grit excelling at heavy stock removal and weld grinding applications. Medium grits ranging from 60 to 80 provide balanced performance for general surface preparation and moderate material removal tasks. Fine grits from 100 to 220 deliver superior surface finishes suitable for pre-paint preparation and decorative metalwork applications.

Heat Management and Surface Quality

One of the most significant advantages offered by flap disc technology is superior heat dissipation compared to traditional grinding wheels. The flexible flap construction allows air to circulate freely around the abrasive surface, effectively carrying away heat generated during the grinding process. This improved cooling reduces the risk of workpiece discoloration, warping, or metallurgical changes that can compromise material properties in critical applications.

The overlapping flap design also contributes to smoother surface finishes by minimizing the gouging and deep scratches commonly associated with conventional grinding wheels. Each individual flap conforms to surface irregularities, creating more uniform material removal patterns and reducing the need for subsequent finishing operations. This characteristic makes flap discs particularly valuable for visible surfaces and applications where surface quality directly impacts final product appearance.

Selection Criteria for Optimal Performance

Grit Size Considerations

Proper grit selection represents the most critical factor in achieving desired results with any abrasive application. Coarse grits below 60 excel at rapid material removal, weld grinding, and heavy surface preparation tasks where aggressive cutting action is required. These grades work particularly well for removing mill scale, heavy rust, or substantial amounts of base material in preparation for welding or machining operations.

Medium grits ranging from 60 to 100 provide excellent versatility for general metalworking applications, offering reasonable material removal rates while producing acceptable surface finishes for most industrial purposes. Fine grits above 100 focus primarily on surface finishing and blending operations, creating smooth surfaces suitable for painting, plating, or other decorative treatments. Understanding these distinctions allows users to select appropriate grades for specific project requirements and avoid unnecessary tool changes during multi-stage operations.

Backing Plate Materials and Configurations

The backing plate material significantly influences both performance characteristics and operational safety in demanding applications. Fiberglass reinforced plates offer excellent strength-to-weight ratios and maintain dimensional stability under high rotational speeds and heavy loading conditions. These plates resist cracking and provide consistent performance throughout the disc's operational life, making them suitable for professional fabrication environments.

Plastic backing plates typically cost less but may exhibit reduced durability under extreme conditions or when used with powerful angle grinders exceeding recommended speed ratings. However, they often provide adequate performance for light-duty applications and occasional use scenarios. The backing plate's hub configuration must match the grinder's spindle system, with most applications requiring standard 5/8-11 threaded attachments or quick-change mounting systems for rapid tool changes.

Industrial Applications and Use Cases

Welding and Fabrication Operations

Professional welding and fabrication shops rely heavily on flap disc technology for preparing joint surfaces, removing weld spatter, and finishing completed assemblies. The ability to transition seamlessly from aggressive material removal to fine surface finishing makes these tools invaluable for maintaining production schedules while achieving consistent quality standards. Coarse grade discs effectively remove mill scale and surface contaminants that can compromise weld penetration and joint strength.

Post-welding operations benefit significantly from medium to fine grit flap discs that can blend weld profiles smooth with adjacent base material surfaces. This capability proves especially valuable in architectural metalwork and decorative applications where visual appearance directly impacts customer satisfaction. The controlled material removal characteristics of flap discs reduce the risk of undercutting or excessive material removal that could weaken finished joints.

Maintenance and Repair Applications

Maintenance professionals across various industries utilize flap disc technology for equipment refurbishment, surface restoration, and component repair operations. The versatility of these tools makes them ideal for field service applications where carrying multiple specialized abrasives would be impractical. Rust removal, paint stripping, and surface preparation for protective coatings represent common maintenance tasks well-suited to flap disc capabilities.

The superior conformability of flap disc construction allows effective work on curved surfaces, corners, and complex geometries that challenge conventional grinding wheels. This flexibility extends tool utility in automotive body repair, marine maintenance, and architectural restoration projects where surface accessibility may be limited. The reduced risk of gouging and overcutting makes flap discs particularly valuable when working on expensive components where replacement costs are significant.

Safety Considerations and Best Practices

Personal Protective Equipment Requirements

Working with any abrasive tool requires comprehensive personal protective equipment to prevent injury from flying debris, dust exposure, and potential tool failure. Safety glasses with side shields provide minimum eye protection, though full-face shields offer superior coverage for heavy grinding operations. Hearing protection becomes essential during extended use periods, as angle grinders typically generate noise levels exceeding safe exposure limits.

Respiratory protection requirements vary based on material being processed and work environment ventilation. Dust masks provide adequate protection for general steel grinding in well-ventilated areas, while powered air-purifying respirators may be necessary when working with exotic alloys or in confined spaces. Cut-resistant gloves protect hands from sharp workpiece edges, though care must be taken to avoid loose-fitting gloves that could become entangled in rotating equipment.

Tool Operation and Maintenance Guidelines

Proper tool operation begins with verifying speed compatibility between the selected flap disc and grinder specifications. Exceeding manufacturer-recommended RPM ratings can result in catastrophic disc failure and serious injury. Most industrial flap discs are rated for speeds up to 13,300 RPM, making them compatible with standard 4.5-inch and 5-inch angle grinders used in metalworking applications.

Regular inspection of both the disc and mounting system helps identify potential safety issues before they result in equipment failure. Worn or damaged backing plates should be replaced immediately, as structural integrity directly affects operational safety. Proper storage in dry environments prevents moisture absorption that could weaken adhesive bonds and lead to premature flap separation during use.

FAQ

What is the typical lifespan of a flap disc in industrial applications

The operational lifespan of a flap disc varies significantly based on application parameters, material hardness, and operator technique. Under normal metalworking conditions, a quality flap disc typically provides 15-30 minutes of continuous grinding time, processing approximately 10-20 square feet of steel surface. Heavy-duty applications with harder materials may reduce this to 8-12 minutes, while light finishing work on softer metals could extend operational life beyond 45 minutes. Factors such as applied pressure, traverse speed, and material removal requirements directly influence disc consumption rates.

Can flap discs be used on stainless steel without contamination concerns

Standard flap discs containing iron-based abrasives can cause contamination when used on stainless steel, potentially leading to corrosion issues in the finished product. Specialized stainless steel flap discs manufactured with iron-free abrasives and contamination-free production processes are available for these applications. These premium discs typically cost 20-40% more than standard versions but provide essential protection for critical stainless steel components in food processing, pharmaceutical, and marine applications where contamination could compromise performance or safety.

How do flap discs compare to traditional grinding wheels in terms of cost effectiveness

While flap discs typically cost 2-3 times more than comparable grinding wheels initially, they often provide superior value through longer operational life and eliminated tool changes. The ability to perform multiple operations with a single disc reduces labor costs and improves productivity in professional environments. Additionally, the superior surface finishes achieved with flap discs can eliminate subsequent sanding or finishing operations, further improving overall project economics. Total cost analysis should consider material removal rates, surface quality requirements, and labor efficiency rather than just initial purchase price.

What maintenance practices extend flap disc operational life

Proper storage in controlled environments prevents moisture absorption and adhesive degradation that can cause premature flap separation. Avoiding excessive pressure during operation allows the disc to cut efficiently while preventing overheating and rapid wear. Regular cleaning of accumulated material buildup using disc conditioning tools or wire brushes maintains cutting efficiency and prevents loading. Rotating work techniques that vary contact points across the disc surface promote even wear patterns and maximize overall tool life. Operating within manufacturer-specified speed ranges prevents centrifugal stress that could damage the backing plate or flap attachment system.