Industrial professionals and metalworkers understand that achieving optimal performance from abrasive tools requires more than just selecting the right product. The longevity and effectiveness of your grinding operations depend heavily on proper maintenance practices that extend tool life while maintaining consistent results. Professional workshops that implement systematic care routines for their abrasive equipment report significant cost savings and improved productivity across their operations.

When working with abrasive wheels in demanding industrial environments, understanding the fundamental principles of tool preservation becomes essential for maintaining operational efficiency. These specialized grinding tools face extreme conditions including high temperatures, varying pressures, and constant contact with different materials. Without proper care protocols, even the highest quality abrasive products can deteriorate prematurely, leading to increased replacement costs and project delays.

Manufacturing facilities worldwide have discovered that implementing comprehensive maintenance strategies for their abrasive equipment results in measurable improvements in both performance and cost-effectiveness. The key lies in developing systematic approaches that address storage conditions, usage patterns, and regular inspection procedures that identify potential issues before they impact productivity.

Understanding Abrasive Tool Construction and Wear Patterns

Material Composition and Performance Characteristics

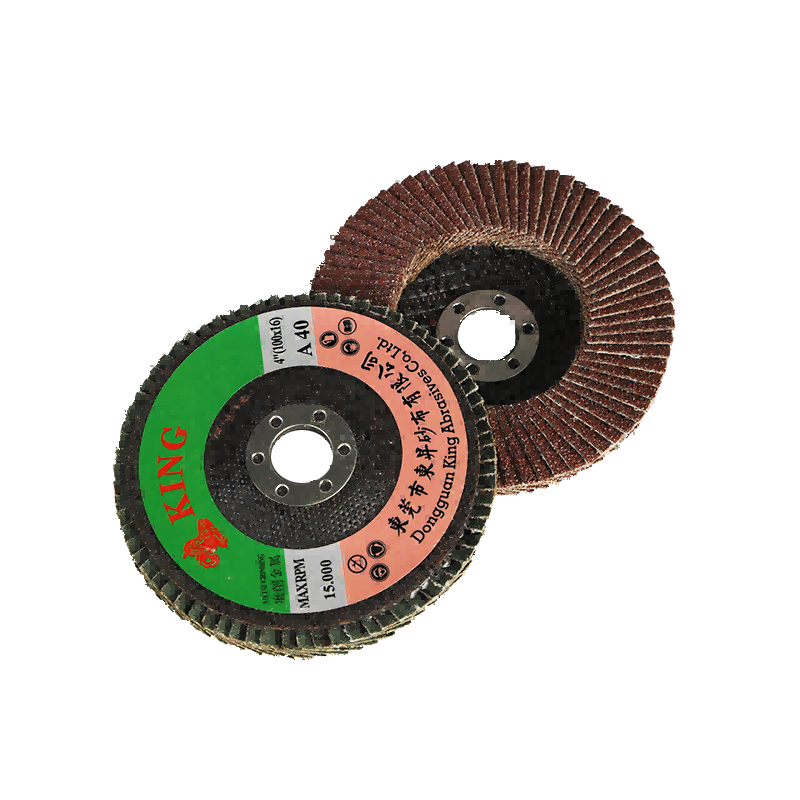

Modern abrasive wheels feature sophisticated engineering that combines aluminum oxide or zirconia alumina grains with specialized backing materials designed to withstand industrial applications. The grain structure determines cutting efficiency and heat dissipation properties, while the backing material provides flexibility and durability during operation. Understanding these components helps operators make informed decisions about usage parameters and maintenance schedules.

Different grain compositions exhibit varying wear characteristics under specific operating conditions. Aluminum oxide variants excel in general-purpose applications on steel and ferrous materials, while zirconia alumina formulations deliver superior performance on stainless steel and high-alloy materials. The bond strength between grains and backing directly influences tool longevity and requires careful consideration during selection and use.

Identifying Normal vs Abnormal Wear Indicators

Professional operators develop expertise in recognizing wear patterns that indicate proper tool function versus those suggesting maintenance issues or incorrect usage. Normal wear appears as gradual grain dulling with consistent backing material integrity, while problematic wear manifests as uneven grain loss, backing delamination, or excessive heat generation during operation.

Regular visual inspection reveals important information about operating conditions and helps predict remaining tool life. Operators should monitor grain exposure, backing flexibility, and overall wheel balance to maintain optimal performance. Documentation of wear patterns across different applications provides valuable data for refining maintenance protocols and usage guidelines.

Optimal Storage Conditions and Environment Control

Climate Control Requirements

Proper storage environments significantly impact abrasive tool longevity by preventing moisture absorption and temperature-related degradation. Humidity levels above 60% can compromise adhesive bonds within the wheel structure, while extreme temperature fluctuations cause expansion and contraction that weakens grain attachment. Climate-controlled storage areas maintain consistent conditions that preserve tool integrity.

Professional facilities invest in dehumidification systems and temperature monitoring equipment to ensure storage areas remain within optimal ranges. These controlled environments prevent corrosion of metallic components and maintain backing material flexibility throughout extended storage periods. Regular monitoring of environmental conditions helps identify potential issues before they affect tool performance.

Physical Storage Best Practices

Horizontal storage positions prevent warping and distortion that can occur when abrasive wheels remain in vertical orientations for extended periods. Purpose-built storage racks distribute weight evenly and prevent contact between individual wheels that could cause surface damage or grain displacement. Proper spacing allows air circulation while protecting tools from dust accumulation and physical impact.

Inventory rotation systems ensure older stock receives priority usage while maintaining product freshness throughout the supply chain. Dating systems and visual inspection schedules help identify tools requiring immediate use or disposal due to age-related deterioration. These systematic approaches minimize waste while ensuring consistent performance across all applications.

Pre-Use Inspection and Preparation Protocols

Visual Assessment Techniques

Comprehensive pre-use inspections identify potential safety hazards and performance issues before tools enter service. Operators examine backing materials for cracks, delamination, or excessive wear that could lead to catastrophic failure during operation. Surface irregularities, missing grains, or contamination require immediate attention to prevent equipment damage or operator injury.

Systematic inspection procedures include checking wheel balance, measuring thickness variations, and verifying proper mounting hole integrity. These assessments ensure safe operation while maximizing tool effectiveness throughout the intended service life. Documentation of inspection results provides traceability and helps identify recurring issues that may require process modifications.

Mounting and Balance Verification

Proper mounting procedures ensure optimal tool performance while preventing premature wear or safety hazards during operation. Correct arbor sizing prevents excessive stress concentration while maintaining secure attachment throughout grinding operations. Balance verification eliminates vibration that causes uneven wear and reduces surface finish quality on workpieces.

Professional operators use precision measuring instruments to verify mounting accuracy and wheel concentricity before beginning work. These procedures identify potential issues that could compromise results or create safety hazards during high-speed operations. Regular calibration of measuring equipment ensures consistent accuracy across all inspection activities.

Operating Parameters and Speed Management

Speed Selection Guidelines

Operating speed selection directly influences tool life and performance characteristics across different applications and materials. Excessive speeds generate heat that breaks down adhesive bonds and causes premature grain loss, while insufficient speeds reduce cutting efficiency and increase operator fatigue. Manufacturer specifications provide baseline parameters that require adjustment based on specific application requirements.

Different materials require customized speed profiles to achieve optimal results while maximizing flap disc longevity. Harder materials typically benefit from moderate speeds that allow proper grain engagement, while softer materials may require higher speeds to prevent loading and maintain cutting action. Experience and documentation help operators develop material-specific speed profiles that balance productivity with tool life.

Pressure and Feed Rate Optimization

Applied pressure during grinding operations significantly affects both removal rates and tool wear patterns. Excessive pressure generates heat while preventing proper grain self-sharpening, leading to glazing and reduced cutting efficiency. Insufficient pressure fails to engage grains effectively, resulting in poor surface finish and extended cycle times that reduce overall productivity.

Optimal pressure application requires understanding material properties and desired surface characteristics. Operators develop sensitivity to feedback from the grinding process, adjusting pressure based on sound, vibration, and visual cues that indicate proper tool engagement. Consistent pressure application throughout the grinding cycle ensures uniform wear and predictable tool life across similar applications.

Cleaning and Maintenance During Use

Debris Removal Techniques

Regular cleaning during grinding operations prevents material buildup that reduces cutting efficiency and causes premature tool wear. Metal particles, paint residue, and other contaminants fill spaces between abrasive grains, creating glazed surfaces that generate excessive heat and poor surface finish. Systematic cleaning procedures restore cutting action and extend operational life.

Cleaning stick applications effectively remove loaded materials without damaging the abrasive structure or compromising wheel integrity. These specialized tools break up accumulated debris while exposing fresh cutting surfaces that restore original performance characteristics. Regular cleaning intervals prevent severe loading that requires aggressive restoration procedures or premature tool replacement.

Dressing and Reconditioning Methods

Professional dressing techniques restore abrasive wheel cutting action by removing glazed surfaces and exposing sharp grain edges. Diamond dressing tools provide precise control over surface conditioning while maintaining wheel geometry and balance. Proper dressing procedures extend tool life significantly while ensuring consistent performance throughout the service period.

Reconditioning schedules depend on application severity and material characteristics, with frequent light dressing proving more effective than infrequent aggressive treatments. Operators monitor surface conditions continuously, applying dressing techniques before performance degradation affects workpiece quality. This proactive approach maximizes productivity while minimizing tool replacement costs.

Heat Management and Cooling Strategies

Temperature Control Methods

Heat generation during grinding operations poses significant challenges to tool longevity and workpiece integrity. Excessive temperatures break down adhesive bonds within the wheel structure while causing workpiece distortion and surface damage. Effective cooling strategies maintain acceptable operating temperatures throughout extended grinding cycles.

Flood coolant systems provide continuous temperature control while flushing debris from the grinding zone. Proper coolant selection ensures compatibility with both the abrasive tool and workpiece material, preventing corrosion or contamination issues. Flow rate and pressure optimization maximizes cooling effectiveness while minimizing fluid consumption and disposal costs.

Air Cooling and Ventilation

Air cooling systems offer alternatives to liquid coolants in applications where contamination concerns or environmental restrictions limit fluid use. High-velocity air streams remove heat and debris while maintaining clean working conditions. Proper nozzle positioning and flow control ensure effective cooling without interfering with operator visibility or workpiece handling.

Ventilation systems remove heated air and grinding debris from the work area, improving operator comfort while protecting equipment from dust accumulation. Filtration components capture airborne particles that could damage precision machinery or create health hazards. Regular maintenance of air handling equipment ensures consistent performance throughout demanding production schedules.

Quality Monitoring and Performance Assessment

Surface Finish Evaluation

Consistent monitoring of surface finish quality provides early indication of tool condition changes that may require maintenance intervention. Surface roughness measurements track performance trends while identifying optimal tool replacement timing. Professional operators use calibrated instruments to document finish characteristics across different applications and operating conditions.

Comparative analysis of surface quality over time reveals patterns that help optimize maintenance schedules and operating parameters. Documentation of finish measurements provides objective data for evaluating tool performance and justifying maintenance investments. These systematic approaches ensure consistent quality while maximizing tool utilization efficiency.

Productivity Metrics and Cost Analysis

Comprehensive tracking of removal rates, cycle times, and tool consumption provides quantitative assessment of maintenance program effectiveness. Cost per unit calculations include tool expenses, labor time, and overhead factors that determine true operational costs. Regular analysis identifies opportunities for improvement while validating maintenance investment decisions.

Benchmark comparisons against industry standards help identify areas where maintenance programs excel or require enhancement. Performance data collection enables data-driven decision making about tool selection, operating parameters, and maintenance intervals. These analytical approaches maximize return on investment while ensuring competitive operational costs.

Safety Considerations and Risk Management

Personal Protective Equipment Requirements

Comprehensive safety protocols protect operators from hazards associated with abrasive wheel operations and maintenance activities. Eye protection prevents injury from flying debris, while respiratory equipment filters harmful particles generated during grinding operations. Proper protective equipment selection considers specific hazards present in each application environment.

Regular inspection and replacement of protective equipment ensures continued effectiveness throughout demanding work cycles. Training programs educate operators about proper equipment use while emphasizing the importance of consistent compliance with safety protocols. These systematic approaches minimize injury risks while maintaining productive operations.

Emergency Procedures and Response Protocols

Well-defined emergency procedures address potential hazards including wheel failure, equipment malfunction, or operator injury scenarios. Clear communication protocols ensure rapid response while minimizing confusion during critical situations. Regular drills and training sessions maintain operator readiness while identifying areas for procedure improvement.

Emergency equipment placement and maintenance ensures availability when needed while preventing interference with normal operations. First aid supplies, fire suppression equipment, and communication devices require regular inspection and testing. These preparedness measures provide confidence while demonstrating commitment to operator safety throughout all maintenance and operational activities.

FAQ

What factors most significantly impact flap disc longevity

Operating speed, applied pressure, and material compatibility represent the primary factors affecting tool life. Excessive speeds generate heat that breaks down adhesive bonds, while improper pressure application causes uneven wear patterns. Material hardness and composition determine optimal operating parameters that balance productivity with tool longevity. Proper parameter selection based on manufacturer recommendations and application requirements maximizes tool life while ensuring consistent performance.

How frequently should abrasive wheels undergo cleaning during extended operations

Cleaning frequency depends on material characteristics and operating conditions, with softer materials requiring more frequent attention due to loading tendencies. Visual monitoring of wheel surface condition provides the most reliable indicator of cleaning needs, with glazed appearances or reduced cutting action signaling immediate attention requirements. Most applications benefit from cleaning every 15-30 minutes of continuous operation, though severe conditions may require more frequent intervention.

What storage conditions provide optimal preservation of unused abrasive tools

Climate-controlled environments with humidity levels below 50% and stable temperatures between 60-75°F provide ideal storage conditions. Horizontal positioning prevents warping while adequate spacing allows air circulation without physical contact between tools. Protection from direct sunlight, dust accumulation, and chemical exposure ensures maximum shelf life. Inventory rotation systems maintain product freshness while preventing age-related deterioration.

When should operators consider tool replacement versus reconditioning

Tool replacement becomes necessary when backing material shows signs of delamination, cracking, or excessive wear that compromises structural integrity. Reconditioning remains viable when surface glazing occurs without underlying damage, allowing restoration through dressing procedures. Cost analysis comparing reconditioning expenses against replacement costs helps determine the most economical approach. Safety considerations always take precedence over economic factors in replacement decisions.

Table of Contents

- Understanding Abrasive Tool Construction and Wear Patterns

- Optimal Storage Conditions and Environment Control

- Pre-Use Inspection and Preparation Protocols

- Operating Parameters and Speed Management

- Cleaning and Maintenance During Use

- Heat Management and Cooling Strategies

- Quality Monitoring and Performance Assessment

- Safety Considerations and Risk Management

- FAQ